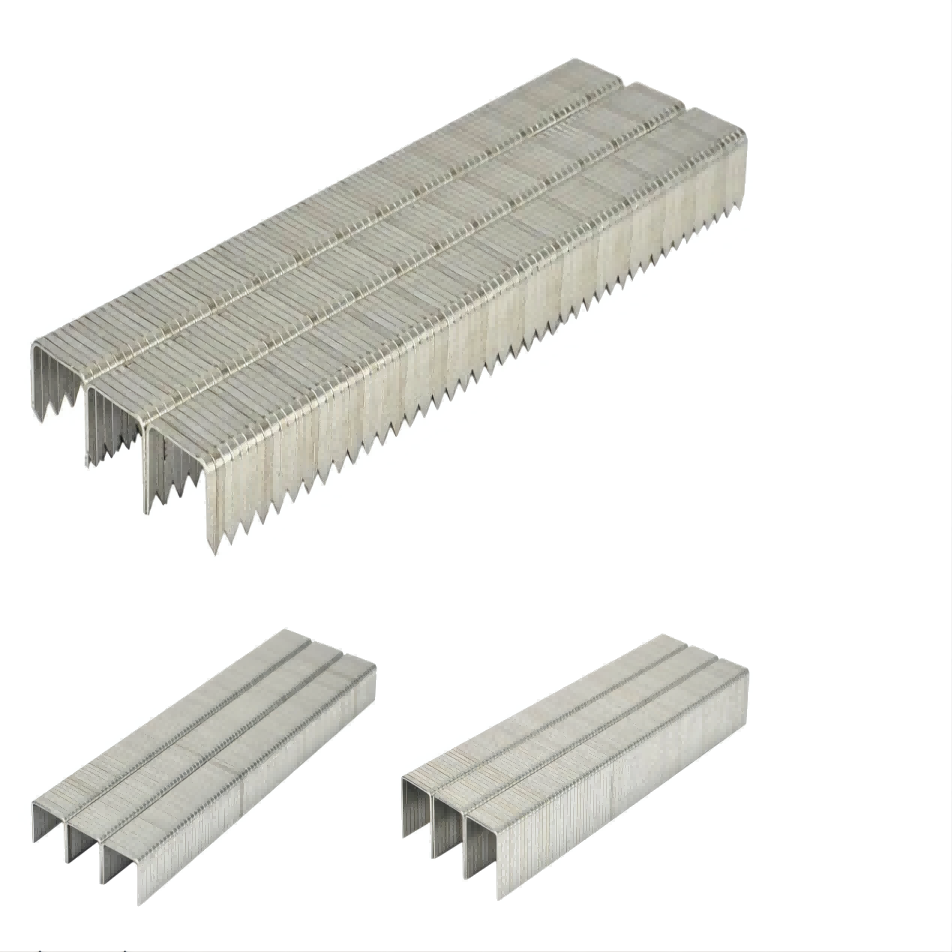

Kev Cai Carbon Steel Hlau Stamping Part nrog Hmoov Coated

Txoj kev ua:CNC tig, CNC milling, stamping, drilling, sib tsoo thiab lwm yam.

Kev kho cua sov:Thermal Refining, Normalizing, Quenching thiab lwm yam.

Kev kho deg:Anodize, Chromate, Electrolytic Plating, Nickel Plating, Galvanize, Tempered, Xim, Hmoov Txheej, Polish thiab lwm yam.

Daim ntawv thov:Manufacturing Machinery, Electronics, IndustrialEqupment, Hluav taws xob, Kev tsim kho & Kho kom zoo nkauj, teeb pom kev zoo, Auto Accessories, Tsheb thauj mus los, Kev Kho Mob, Khoom Siv Computer, Kev Ua Liaj Ua Teb & Khoom Noj thiab lwm yam.

Daim duab hom:PRO/E, CAD, Solid works, IGS, UG, CAM, CAE, PDF.

Kev Pabcuam:Raws li cov neeg siv khoom xav tau, muab cov qauv tsim, kev tsim khoom thiab kev pabcuam, kev tsim pwm, thiab kev ua haujlwm kom muaj kev pabcuam ib-nres.

Lub sij hawm xa tuaj:7-30 hnub

Ntim:EPE ua npuas ncauj / xeb pov thawj daim ntawv / Stretch zaj duab xis / hnab yas + thawv

MOQ:Sib tham tau

FAQ

1.Dab tsi yog peb qhov zoo dua lwm tus?

a).Stamping, Machining, Vuam, Tuag casting thiab Surface kho cov cuab yeej tau nruab rau kev muab koj cov kev pabcuam zoo tshaj plaws thiab kev daws teeb meem.

b).45 xyoo kev paub.

c).Kev xa khoom raws sijhawm.

e).Strict Quality Control System: 100% kev soj ntsuam ua ntej ua zaub mov xa tuaj.

2.Dab tsi yog lub peev xwm ntau lawm ntawm koj lub tuam txhab?

a).Nyob rau hauv Merid, fabrication ua hauj lwm muaj xws li precision stamping, sib sib zog nqus nqus nqus, nplua blanking, cnc xuas nrig ntaus, cnc dabtsi yog khoov, laser txiav, nplaim txiav, cnc milling, cnc tig, raj dabtsi yog khoov, txhuas extruding, vuam,

tuag casting, thiab lwm yam.

b).Cov khoom siv hlau muaj xws li stainless hlau, hlau, carbon steel, caij nplooj ntoos hlav steel, txhuas, titanium, tooj liab, tooj dag, tooj dag thiab lwm yam.

3.Dab tsi equipments koj muaj?

a).Punch Xovxwm: 16T-500T.

b).Vuam: Carbon dioxide vuam, chaw vuam, tig vuam, automated robotic vuam.

c).Machining: CNC tshuab dhos thiab tshuab chaw, lub teeb tshuab (drilling, milling thiab tapping).

d).Tuag casting: 80T-500T.

e).Deg kev kho mob: tua blasting chaw, Polishing, Deburring.

4.Dab tsi tiav koj tuaj yeem muab tau?

Cov khoom tiav uas peb tuaj yeem muab tau yog hmoov txheej, pleev xim, galvanizing, ci enamel, anodizing tiav, thiab lwm yam plating tiav.

5.Koj tuaj yeem lav qhov zoo li cas?

Lub tuam tsev tswj xyuas kev ua tau zoo tsim cov phiaj xwm tswj ua ntej pib qhov project, kev tshuaj xyuas nruj yuav raug siv thoob plaws tag nrho cov khoom.